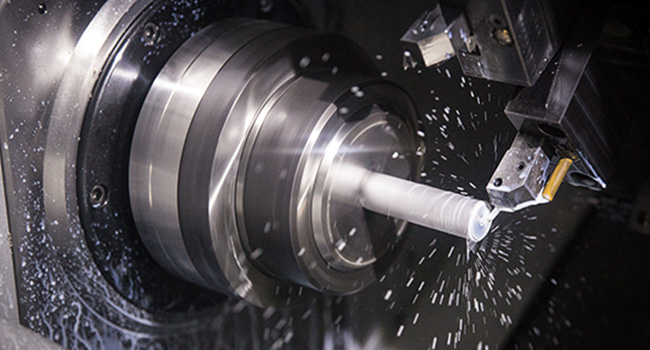

Machining Envelope

- CNC Milling – Vertical: X=60” Y=26” Z=26”

- CNC Milling – 5 Axis Vertical: ‘B’ Axis swing=31” X=64” Y=32” Z=30”

- CNC Milling – Horizontal: X=22” Y=26” Z=20”

- CNC Turning: 13” Swing X 44” Between Centers

- Manual Turning: 60” Swing X 420” Between Centers

- Broaching: Customized to meet specific requirements

- O.D. Grinding: 14” Swing X 36” Between Centers

- I.D. Grinding: 8” Swing X 24” Long

- Centerless Grinding: X=12” Y=24” Z=14”

- Surface Grinding: X=12” Y=24” Z=14”

- Jig Grinding: X=22” Y=28” Z=20”

- Lapping: 11” Dia. Workpiece (or larger depending on part shape)

- I.D. Honing: Up To 6.5” Dia.

Typical Outsourced Special Processes

Thermal Processes

- Vacuum Heat Treatment

- Vacuum Carburization

- Conventional Gas Carburization

- Induction Scanning

- Nitriding

- Cryogenic Treatment

Chemical/Plating Processes

- Thin Dense/Hard Chromium

- IVD Coatings

- Cadmium

- Electroless Nickel

- Copper

- Aluminum

- Anodize

- Electropolish & Passivation

- Dry Film/Chemical Film

- Military Paint Specifications

Specialized Welding

- Electron Beam Welding

- Brazing

Specialized Manufacturing Processes

- Deep-Hole Drilling

- Splining

- Rack-Rolling

- Hobbing

- Gear/Spline Grinding

- Shot Peening

Specialized Inspection Processes

- Eddy Current Inspection

- Radiographic Inspection