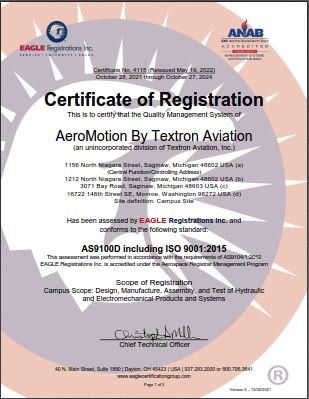

AeroMotion is dedicated to exceeding the needs and expectations of our customers in the manufacturing of precision machined products using modern management, equipment and technology. We are committed to the continuous improvement of our products, services and the effectiveness of our Quality Management System to achieve increased customer satisfaction. We ensure compliance with the requirements of our Quality Management System through review of our quality objectives and adjusting for suitability as necessary.

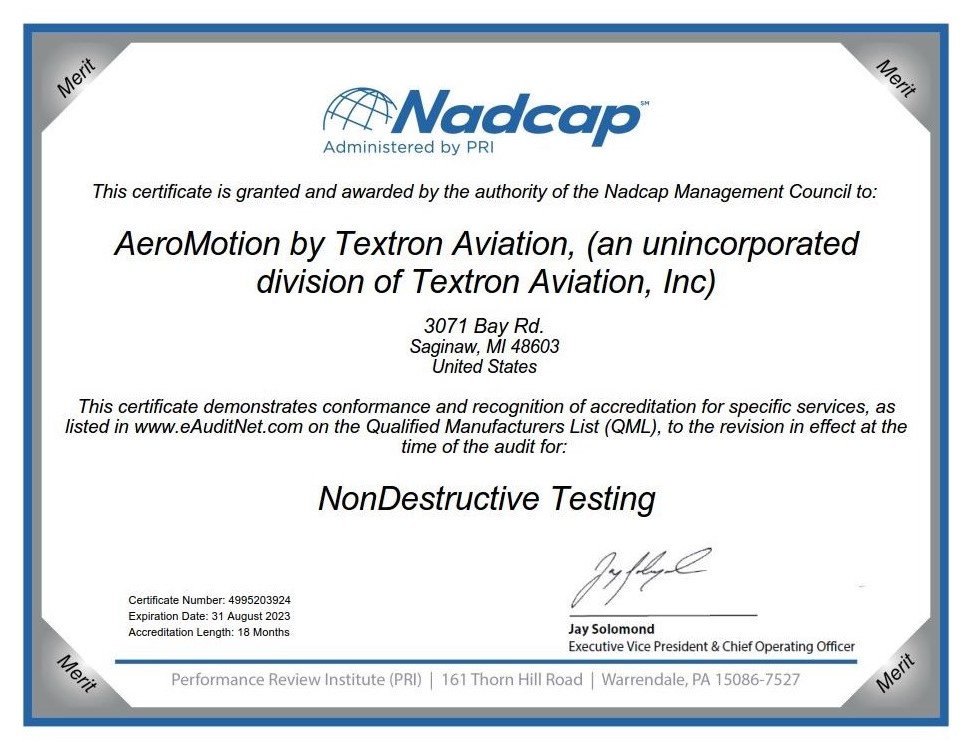

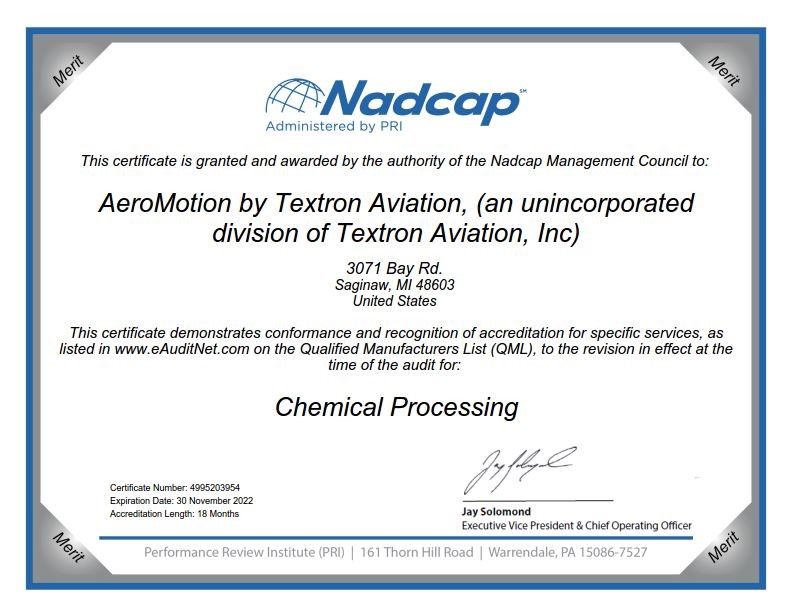

NON-DESTRUCTIVE TESTING LAB – NADCAP ACCREDITED

AeroMotion has an on-site NDT (Non-Destructive Testing Lab), audited by Performance Review Institute (PRI) to the “National Aerospace and Defense Contractors Accreditation”. NADCAP accreditation is issued only after an extensive company-wide audit and multi-level review.

Magnetic Particle Inspection

Magnetic particle inspection is an extremely sensitive testing process used with ferrous materials to detect minute surface cracks. It can also detect some subsurface discontinuities. The process involves creating magnetic fields in a part and detecting the flux leakage at the site of any discontinuities.

Magnetic particle inspection is both fast and accurate making it ideal for large-volume applications in the aerospace and automotive industries.

Liquid Particle Inspection

One of the oldest forms of non-destructive testing, the process involves applying a penetrating liquid to the surface of a part which then collects in any surface cracks. After rinsing, a developer is applied that draws the penetrant out of the cracks making them visible to an inspector.

AeroMotion provides reliable, cost-effective liquid penetrant inspection services for both high-volume applications and individual, large, or complex parts.