Expert Design Engineering

AeroMotion has a robust team of design, manufacturing, and process engineers with significant experience in the machining industry. We utilize state of the art software and equipment to deliver results in the most challenging applications.

- Expert material selection

- Significant in-house testing capability

- Broad network of metallurgical testing laboratories

- Efficiency optimization and acceptance testing

Reverse Engineering / PMA Technical Support

Typical Program Management Responsibility

- Weekly progress reports

- Detailed project timelines

- Risk assessment & mitigation

Typical Design Engineering Package

- Complete technical data package

- Detailed inspection reports of each component

- Summary of metallurgical analysis

- Coordination of PDR & CDR activities

- Coordination of reverse engineering activities

- Interpretation of reverse engineering data

- Usage & determination of industry specification cross reference

- Complete set of working drawings (detail & assemblies A/R)

- Complete assembly process & acceptance test plan

- Creation of parametric NX solid models

- Usage of GD&T per ASME Y14.5M-1994, when applicable

- Detailed material, heat treat & finishes to IAW latest industry specifications

- IAW industry standard drafting practices

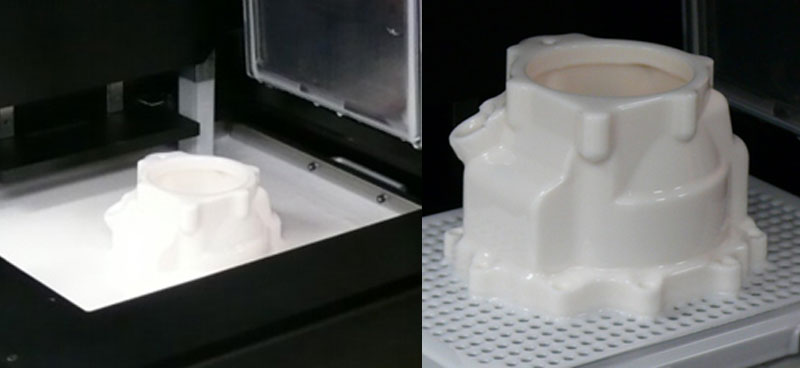

Rapid Prototyping / 3-D Printing Technology

Do you need to make an impact at an upcoming meeting? AeroMotion can provide a prototype built to fit your sales or engineering needs. AeroMotion offers quick turnaround rapid prototyping services utilizing our new Envisiontec Ultra 3SP. Our machine has a build envelope of 10.5” long x 7” wide x 7.5” high with an XY axis resolution of .004” and Z axis resolution of .002”. The Envisiontec Ultra 3SP is a selective photo-cure laser printer which utilizes a Texas Instruments DLP projection system. In this process, voxels are projected through precision optics into photo polymer resin liquid and then cured layer by layer. The photo-cure process yields an extremely high quality, close tolerance part with a finish similar to injection molding.

NADCAP Accredited Non-Destructive Testing Laboratory

AeroMotion’s NADCAP accredited non-destructive laboratory offers both Magnetic Particle Inspection per ASTM E1444 and Liquid Penetrant Inspection per ASTM E1417. Our laboratory features new state-of-the-art Gould-Bass equipment and is managed by our on-site level III technician. All AeroMotion NDT technicians hold a minimum Level II accreditation. We offer quick turnaround for emergent projects while also supporting production contracts.

Passivation Process

AeroMotion offers in-house passivation utilizing a new ESMA Automatic Self-Contained Passivation System. AeroMotion performs both Citric & Nitric Acid processes IAW both AMS 2700 & ASTM A967. Our passivation system features a built-in ultrasonic washer and deionized water rinse while utilizing a water immersion test for acceptance testing.